a few projects.

Here are a few projects I have done, that are a bit longer and more formally documented.

I haven't included things I am currently working on.

Below are links to the projects in chronological order.

ⴵ Atlia

2024-25

Building the next generation of private portfolio management.

Backed by

Y-Combinator

🝆 Foresee

2024-25

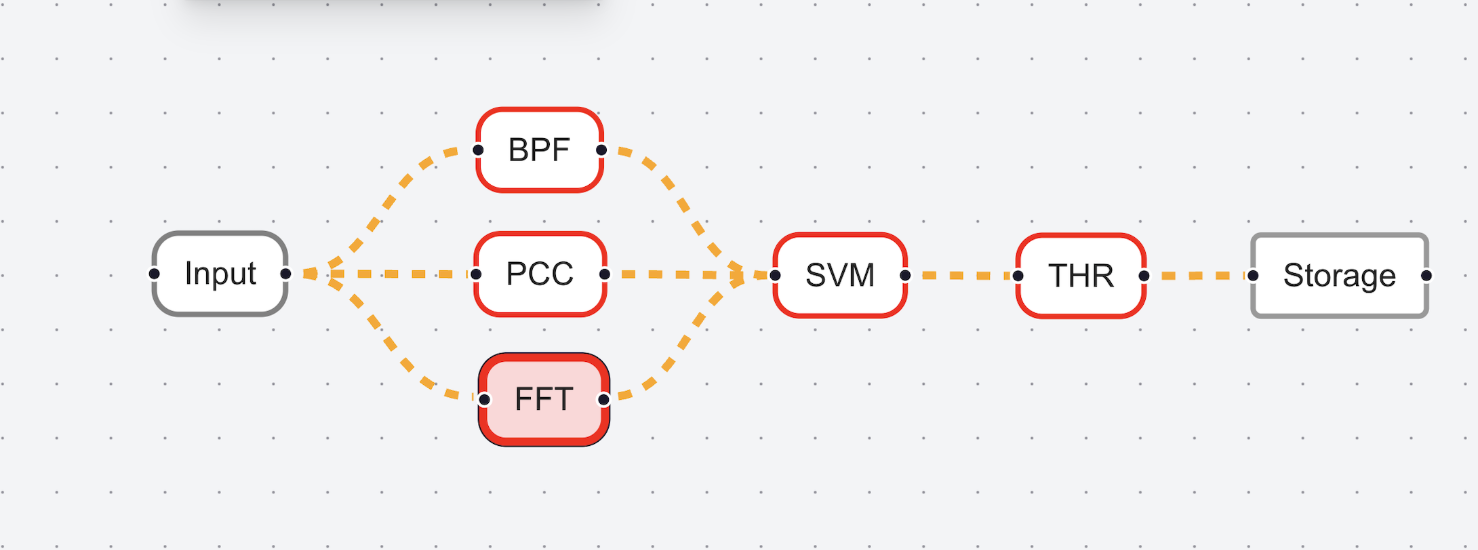

A Modular and Open Framework to Explore Integrated Processing on Brain-Computer Interfaces

Paper accepted at IEEE EMBC 2025

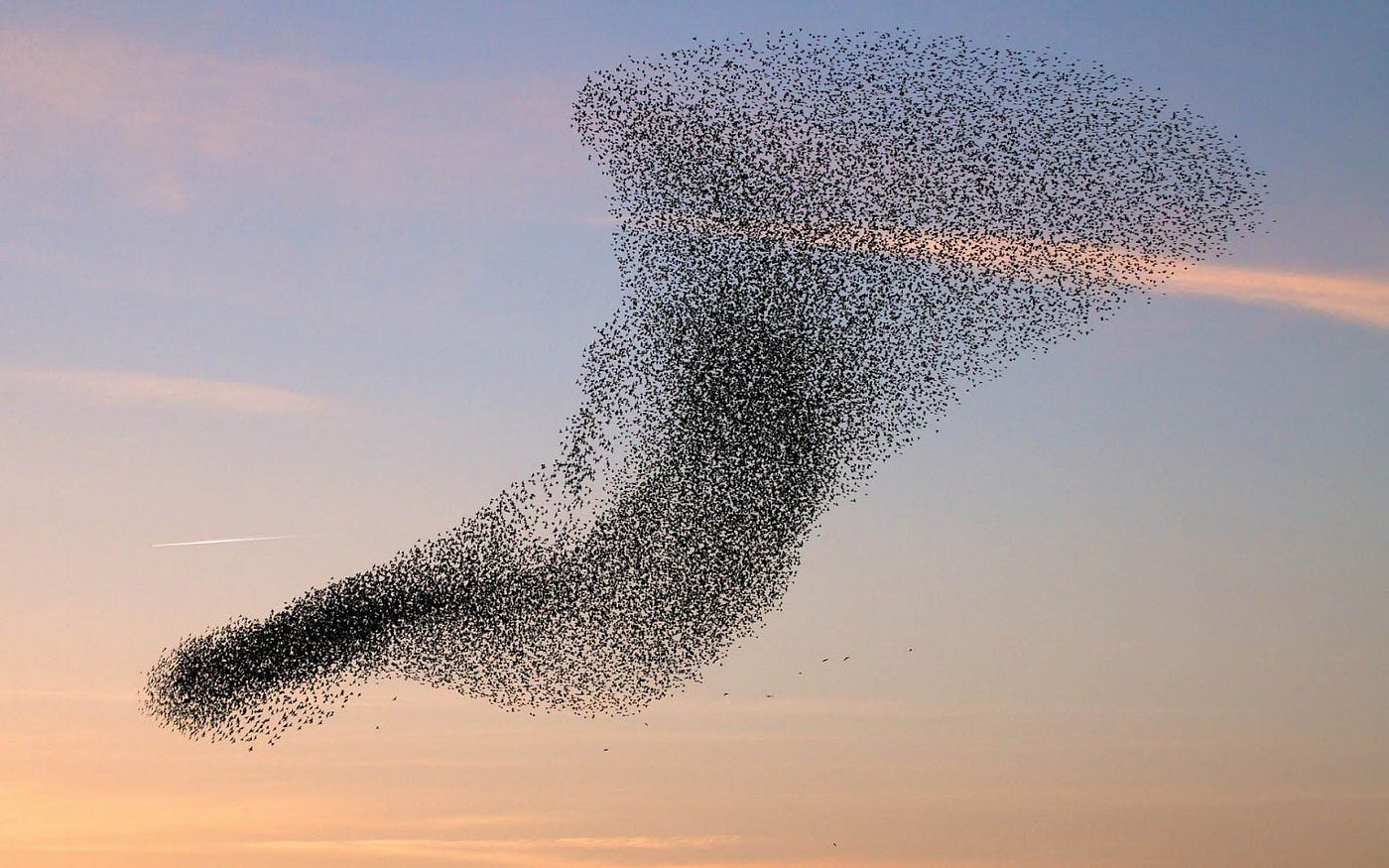

∆ Boids_FPGA

2024

A very fast and efficient hardware (verilog + FPGA) implementation of the boids flocking algorithm.

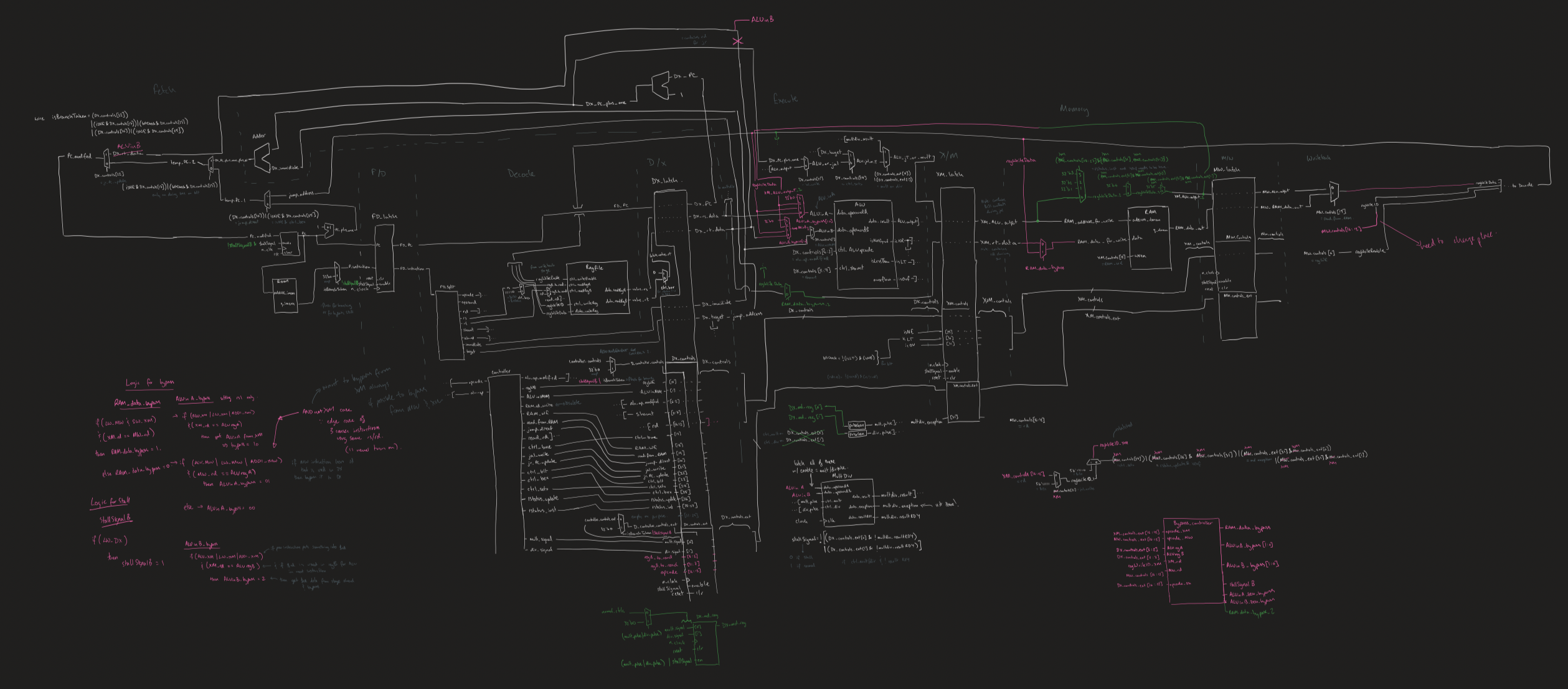

⌘ Verilog_MIPS_CPU

2024

A fully functioning 5 stage, pipelined, bypassed CPU made using Verilog from the ground up.

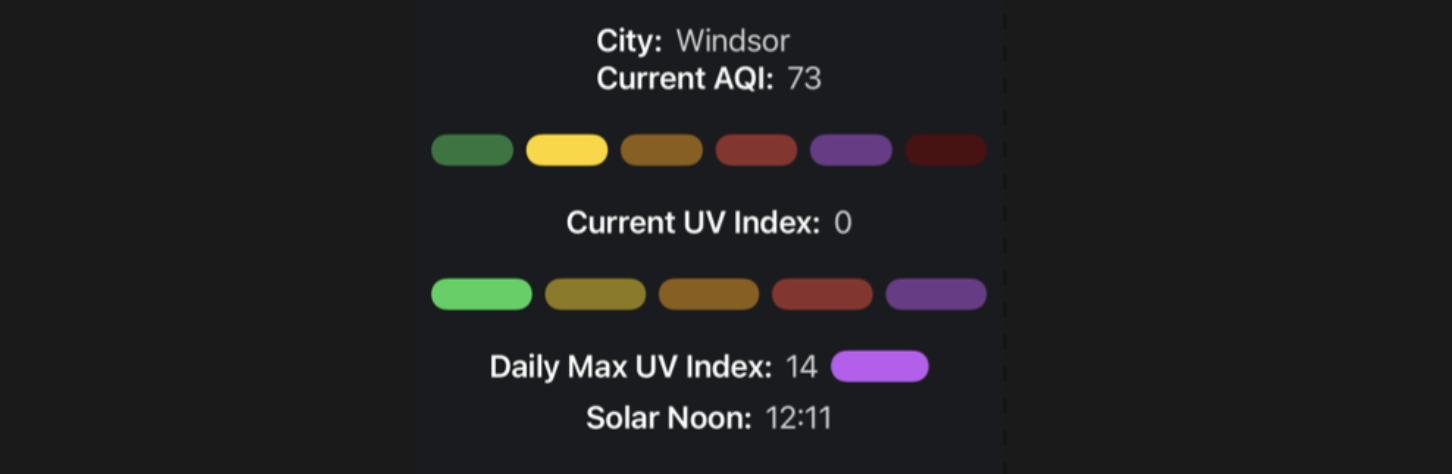

ꐠ Melanoma_Scan

2021-22

An ios app that can detect skin cancer, and provide important environmental and location

based information for melanoma.

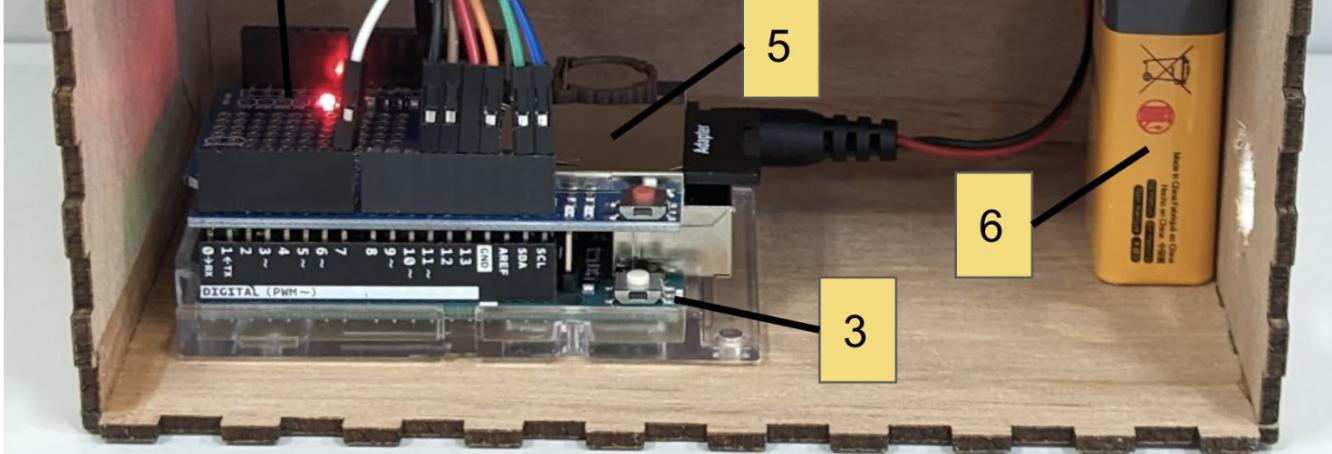

☼ Solar_Panel_Dust_Sensor

2022

A cost-effective arduino project to detect dust on solar panels.

♽ Projects to add

20??

Yale BCI, Checker chip, SAT accelerator